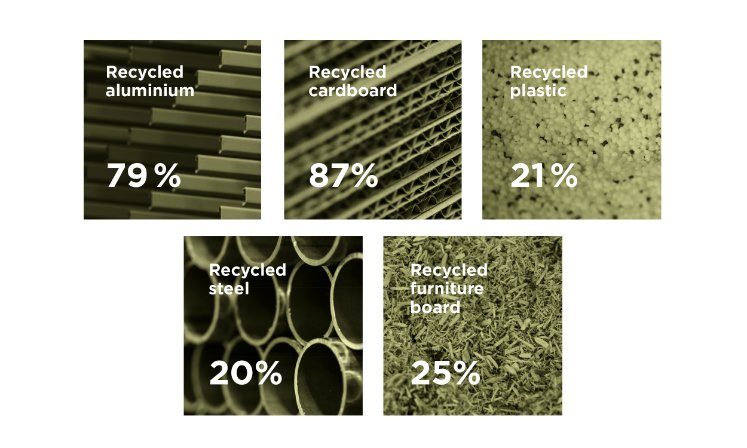

Based on data collected from suppliers for 2023, we can summarize the indicators for recycled and sustainable materials used in our products.

Ecodesign at Nowy Styl

In our activities, Nowy Styl is guided by the idea of sustainable development, which is reflected in every aspect of what we do, including ecodesign. We act at many levels - the finished product, the materials and chemicals used in our products, the production processes, packaging management and logistics.

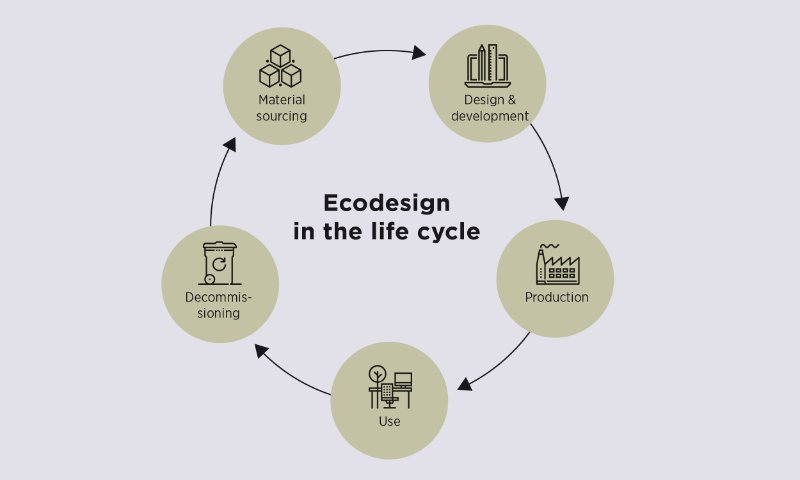

Ecodesign - a holistic approach to products

Our aim is to design products in a way that minimises their environmental impact throughout their life cycle - from conception to production to recycling.

Ecodesign is an approach that takes environmental considerations into account at every stage of the product life cycle. Before we bring a product to market, we carry out a detailed analysis of the environmental impact of its components and production processes. Because we have implemented an ecodesign management system compliant with ISO 14006, we can effectively integrate environmental measures into our design process.

Ecodesign is an approach that takes environmental considerations into account at every stage of the product life cycle. Before we bring a product to market, we carry out a detailed analysis of the environmental impact of its components and production processes. Because we have implemented an ecodesign management system compliant with ISO 14006, we can effectively integrate environmental measures into our design process.

Ecodesign at finished product level

In designing our products, we are guided by several principles that aim to extend their useful life and minimise waste:

These principles are fundamental to implementing circular economy, aiming to reduce the consumption of natural resources and reduce waste.

- Product durability - designing for long-term use.

- Upgradability, part replacement, expansion - our products can be easily disassembled, repaired and expanded.

- Spare parts for our products are available for a period of 5 years from the date on which the relevant product line is withdrawn from production (original functional components or components providing equivalent functionality, with due regard to user safety).

- Recycling - we design for recycling, both in terms of using recycled materials and designing our products to be easily recyclable.

These principles are fundamental to implementing circular economy, aiming to reduce the consumption of natural resources and reduce waste.

Ecodesign at materials and chemicals level

At Nowy Styl, we pay particular attention to the choice of materials and chemicals used in production:

• We do not use harmful substances and analyse them in accordance with European regulations (the substances listed on the SVHC candidate list and in REACH Annexes XIV, XVII).

• We use polyurethane foam free of ozone-depleting foaming agents (CFCs and HCFCs).

• We choose water-based adhesives that are free of organic solvents, and our paint finishes contain no VOCs or heavy metals.

• We use wood-based materials with reduced formaldehyde emissions which come from sustainable, certified sources (FSC®, PEFC).

• Plastic items weighing more than ≥ 50 g are tagged with a recycling code.

• We aim to continuously increase the proportion of recycled materials.

• We do not use harmful substances and analyse them in accordance with European regulations (the substances listed on the SVHC candidate list and in REACH Annexes XIV, XVII).

• We use polyurethane foam free of ozone-depleting foaming agents (CFCs and HCFCs).

• We choose water-based adhesives that are free of organic solvents, and our paint finishes contain no VOCs or heavy metals.

• We use wood-based materials with reduced formaldehyde emissions which come from sustainable, certified sources (FSC®, PEFC).

• Plastic items weighing more than ≥ 50 g are tagged with a recycling code.

• We aim to continuously increase the proportion of recycled materials.

Ecodesign at production processes level

Our production processes are continuously optimised to increase material efficiency, reduce raw material consumption and reduce waste:

• Continuous improvement of material efficiency - by optimising and improving production processes aimed at reducing the consumption of materials needed to make a product, and thereby reducing production waste. Currently, material efficiency depends on the type of production process and is mostly above 70%.

• Waste reduction - production waste, including fabric remnants and metal scraps, is almost entirely recycled, with only a marginal proportion going to landfills (approximately 0.1%).

• Comprehensive management of chemicals - we monitor our use of chemicals, including their impact on the environment, and seek to replace them with more environmentally friendly alternatives (e.g. changing our chrome plating technology - eliminating IV-valent chromium and replacing it with chromium (III))

• Continuous improvement of energy efficiency - we are optimising our production processes to use energy more efficiently and are successively modernising our machinery by replacing it with more energy-efficient equipment. As far as building infrastructure is concerned, we are thermally upgrading our buildings and replacing lights with LEDs.

• Continuous improvement of water efficiency and wastewater treatment process - wherever possible, we strive to implement closed water circuits and detailed monitoring of water consumption at the points where it is most heavily consumed.

• Continuous improvement of material efficiency - by optimising and improving production processes aimed at reducing the consumption of materials needed to make a product, and thereby reducing production waste. Currently, material efficiency depends on the type of production process and is mostly above 70%.

• Waste reduction - production waste, including fabric remnants and metal scraps, is almost entirely recycled, with only a marginal proportion going to landfills (approximately 0.1%).

• Comprehensive management of chemicals - we monitor our use of chemicals, including their impact on the environment, and seek to replace them with more environmentally friendly alternatives (e.g. changing our chrome plating technology - eliminating IV-valent chromium and replacing it with chromium (III))

• Continuous improvement of energy efficiency - we are optimising our production processes to use energy more efficiently and are successively modernising our machinery by replacing it with more energy-efficient equipment. As far as building infrastructure is concerned, we are thermally upgrading our buildings and replacing lights with LEDs.

• Continuous improvement of water efficiency and wastewater treatment process - wherever possible, we strive to implement closed water circuits and detailed monitoring of water consumption at the points where it is most heavily consumed.

Ecodesign at packaging and logistics level

We aim to reduce the environmental impact of our packaging by introducing returnable and reusable packaging. We use protective covers, wooden crates and transport blankets made from recycled materials.

In addition, our logistics solutions reduce the consumption of packaging materials and contribute to the reduction of CO2 emissions, among other things thanks to a BDF swap vehicle body system we have in place.

With double decking, we gain additional transport space in which more chairs and furniture can be stacked. By placing products on two levels we can increase the load capacity of Euro pallets by 63%. Thanks to the BDF system and the reduction in truck traffic, we are reducing harmful emissions by 40%.

In addition, our logistics solutions reduce the consumption of packaging materials and contribute to the reduction of CO2 emissions, among other things thanks to a BDF swap vehicle body system we have in place.

With double decking, we gain additional transport space in which more chairs and furniture can be stacked. By placing products on two levels we can increase the load capacity of Euro pallets by 63%. Thanks to the BDF system and the reduction in truck traffic, we are reducing harmful emissions by 40%.

Certificates and documents for environmentally friendly products

Environmental certificates and other documents for environmentally friendly products are the result and proof of compliance with ecodesign requirements at the various stages of the life cycle of our products. Promoting honesty and transparency in environmental communication, we classify them in accordance with ISO 14020 as recognised environmental declarations:

1. Type I environmental declarations - EN ISO 14024

Awarded by independent certification organisations. Products bearing the Type I label meet specific environmental criteria, including Life Cycle Analysis (LCA) and sustainability requirements. In this context, our selected product lines hold European or national certifications.

Awarded by independent certification organisations. Products bearing the Type I label meet specific environmental criteria, including Life Cycle Analysis (LCA) and sustainability requirements. In this context, our selected product lines hold European or national certifications.

European certifications:

FEMB Level - assessments are made in relation to four impact areas: materials, energy and atmosphere, human and ecosystem health and social responsibility. This certification takes account of European legislation, the principles of green public procurement and the EU circular economy guidelines. It benefits both producers and end users by helping them make decisions and sustainable product choices.

A selection of our product lines are certified to the highest Level 3 (for example, the Xilium chairs link).

Under FEMB Level certification, the product is the 'lens' through which the entire organisation is assessed.

A selection of our product lines are certified to the highest Level 3 (for example, the Xilium chairs link).

Under FEMB Level certification, the product is the 'lens' through which the entire organisation is assessed.

National certifications:

For selected product lines, we hold nationally recognised certifications, including Blue Angel (Germany), NF Environnement, NF Office Excellence (France), and Möbelfakta (Scandinavian countries).

2. Type II environmental declarations - EN ISO 14021

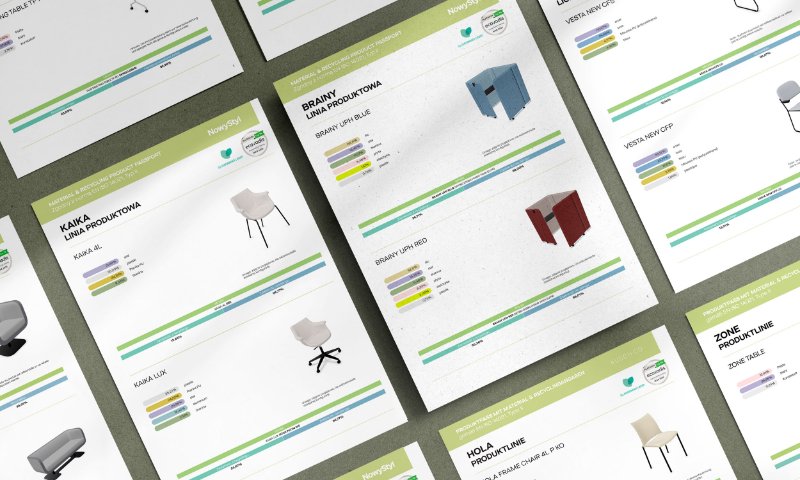

We prepare product and recyclable material passports for our products, featuring information on the product's material composition, origin and recyclability.

We prepare product and recyclable material passports for our products, featuring information on the product's material composition, origin and recyclability.

Product and recycling material passports

We prepare product and recycling material passports for our products, containing information on material composition, origin, and recyclability.

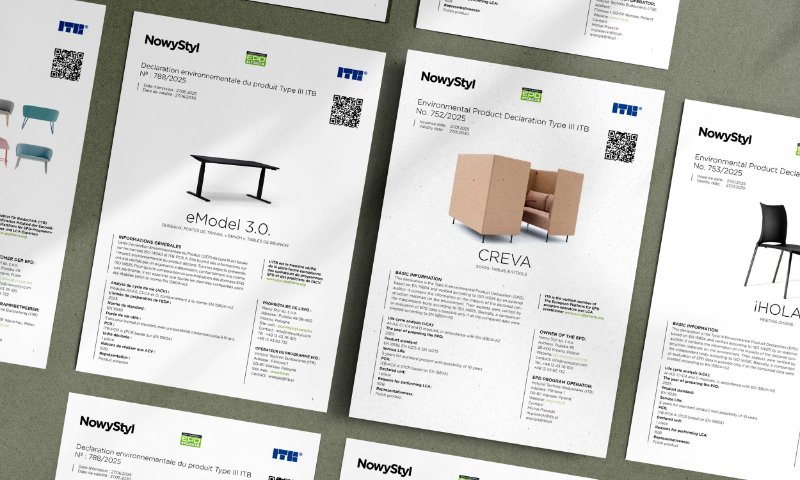

3. Type III environmental declarations - EN ISO 14025

More and more of our product lines have a Type III Environmental Declaration, the so-called EPD. It is an independently verified and officially registered document. It provides transparent and comparable information on the environmental impact of products at different stages of their production and throughout their life cycle.

EPDs

EPDs for Nowy Styl products are prepared by ITB - an institution authorised to issue documents of this type (a member of the European Platform of institutions authorised to issue EPDs: ECO Platform).

An EPD provides information on the environmental impact of the product in question (including global warming potential, i.e. carbon footprint).

We create EPDs based on actual production and raw material consumption data.

An EPD provides information on the environmental impact of the product in question (including global warming potential, i.e. carbon footprint).

We create EPDs based on actual production and raw material consumption data.

Ecodesign in Nowy Styl’s strategy

To us, ecodesign is an integral part of our mission to create environmentally and people-friendly products. By continuously improving our production processes, choosing the right materials and technologies, and taking care to manage our carbon footprint, we are contributing to a sustainable future.